Basalt rebar

Basalt

Basalt is a dark, usually black, extrusive igneous rock consisting of 45-52% SiO2. Most commonly having an aphanitic or porphyritic structure, while having either porous or compact texture.

Basalt fiber

Basalt fibers are divided into continuous and staple fibers. They’re used in both composite and non-composite materials. Basalt staple fibers are used to reinforce chemically hardened polymer composites and thermoplastics. They can also be used in regular and polymer concrete, as well as in mortars and adhesives. What’s most important basalt fibers are a completely natural product, that are formed as a result of melting basalt rock (volcanic lava). Because of that, they are not toxic and they do not emit harmful compounds into the atmosphere.

Continuous fibers are becoming more popular than staple ones. That’s because they can be used in a wider number of applications. We can mention rovings, i.e. long and narrow bundles of fibers, but also textiles and yarns that are used in various end product industries, including production of vehicle interior finishing materials, sports goods, in the process of generating wind energy, in construction and for the reinforcement of pipelines and liquid tanks.

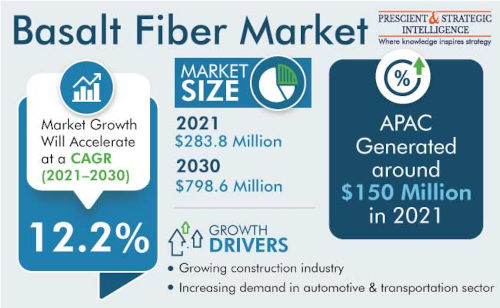

Global basalt fiber market is on a constant rise.

Main factors for the market cap increase are:

- growing automotive sector in developing countries

- increasing interest in ecological and recyclable materials

- newest technological developments in the basalt fiber field.

Composite Basalt Rebar

(BFRP Basalt Fiber Reinforced Polymer)

Basalt rebar is a rod with continual spiral ribbing. They’re a prospective material with a wide use in building. Many test results show that long standing structures where basalt rebar was used highly surpasses life expectancy of structures where different materials were used.

Basalt Rebar:

• Three times stronger than steel rebar (Basalt rebar’s strength is around 800-1400 MPa, depending on diameter, while steel rebar’s strength is around 360-400 MPa)

• Four times lighter than steel rebar with similar diameter and 7-9 times lighter for an even replacement

• High resistance to corrosion

• Poor heat conductivity

• Non-hygroscopic

• Dielectric

• Does not require welding

• Can be tied with wire or plastic clamp

• Similar heat conductivity to concrete which increases construction durability for concrete and cement buildings

• Does not interfere with radio frequencies – in contrast to carbon or steel rebar

Basalt rebar production’s carbon footprint is 90% less than that of steel, while also having the smallest environmental impact in comparison with other FRP

While comparing them to composite glass fiber rebar, basalt rebar has:

• 20-25% higher tensile strength

• 10-15% better modulus of elasticity

• melting point increased by 150 °C and increased operating temperature range

• Increased resistance to acid and rust

• increased resistance to alkalines